In modern manufacturing and assembly, the demand for reliable bonding solutions has grown significantly. One such solution that has gained widespread use across industries is acrylic foam tape. Known for its versatility, strength, and clean finish, acrylic foam tape has become a preferred alternative to traditional mechanical fasteners and liquid adhesives. Whether in automotive, electronics, or construction, this adhesive tape offers performance and durability in demanding environments.

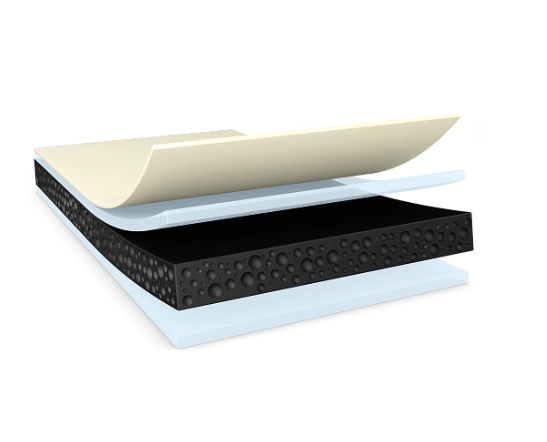

Acrylic foam tape is a double-sided adhesive tape made with high-performance acrylic foam. Unlike conventional tapes, the foam layer plays a crucial role in bonding uneven surfaces and distributing stress over the bonded area. It provides strong adhesion while maintaining a certain degree of flexibility, allowing it to handle expansion, contraction, and vibrations with ease. These characteristics make it ideal for both structural and decorative bonding applications.

Acrylic foam tapes are engineered to deliver high bonding strength, durability, and resistance to environmental factors. The viscoelastic properties of the foam allow it to conform to different substrates, while the acrylic adhesive ensures long-term performance. It can maintain adhesion across a wide range of temperatures and is also resistant to moisture, solvents, and UV light. These tapes are available in various thicknesses and widths, making them adaptable to different surfaces and applications.

One of the key reasons acrylic foam tape is preferred in industrial applications is its exceptional bonding strength. It adheres well to a variety of surfaces including metal, plastic, and glass, creating a permanent seal that can replace traditional screws, rivets, or welds.

Acrylic foam tape is designed to withstand environmental stress such as sunlight, rain, and extreme temperatures. Its UV resistance ensures that the adhesive does not degrade or discolor over time, making it suitable for both indoor and outdoor applications.

The foam core of the tape acts as a cushion, absorbing vibrations and minor shocks. This feature makes it especially valuable in automotive and electronic applications where components are regularly exposed to movement or mechanical stress.

Acrylic foam tape helps achieve a smooth, seamless finish by eliminating the need for visible fasteners. This enhances the overall aesthetics of the product while also reducing potential weak points that can occur with traditional hardware.

In vehicle manufacturing, acrylic foam tape is an automotive tape that is widely used for attaching trims, nameplates, emblems, and mirror assemblies. It simplifies the assembly process, reduces weight, and provides a long-lasting bond that resists automotive wear and weather exposure.

The tape is commonly used in consumer electronics for assembling screens, bonding panels, and securing internal components. Its cushioning properties also protect delicate electronics from vibration and mechanical impact.

Acrylic foam tape plays a vital role in construction, particularly in glass glazing, curtain wall systems, and mounting decorative panels. It accommodates expansion and contraction while maintaining a strong bond, making it ideal for structural and aesthetic installations.

Signmakers rely on acrylic foam tape to mount signage, lightboxes, and display panels. It offers strong adhesion without drilling holes or leaving residue, ensuring the sign remains clean, professional-looking, and easy to install.

Selecting the right acrylic foam tape depends on factors like substrate material, surface texture, environmental exposure, and intended load. For high-stress applications, a thicker tape with high-tack adhesive may be necessary. Outdoor or UV-exposed settings require tapes rated for weather resistance. Compatibility with the materials being bonded is also essential to ensure a secure and lasting connection.

For best results, surfaces should be thoroughly cleaned and dried before applying the tape. Use isopropyl alcohol to remove any oil, dust, or residue. Apply consistent pressure to ensure full surface contact, and allow the adhesive to cure for several hours for maximum bond strength. Avoid repositioning the tape once applied, and store it in a cool, dry place to maintain adhesive quality.

Acrylic foam tape is a highly effective and reliable bonding solution trusted across industries for its strength, flexibility, and clean appearance. Whether you’re assembling car parts, securing glass panels, or installing signage, this tape offers a long-term solution that simplifies installation and enhances performance.

Explore our range of premium acrylic foam tapes at VST Insan and find the perfect fit for your next project today!