Electronics generate heat during operation, and managing that heat is essential to maintain performance, efficiency, and lifespan. One common solution for thermal management is the thermal pad. Whether in computers, gaming consoles, or industrial equipment, thermal pads play a critical role in ensuring that sensitive components do not overheat.

In this guide, we’ll cover what a thermal pad is, how it works, the different types available, and where they are commonly used.

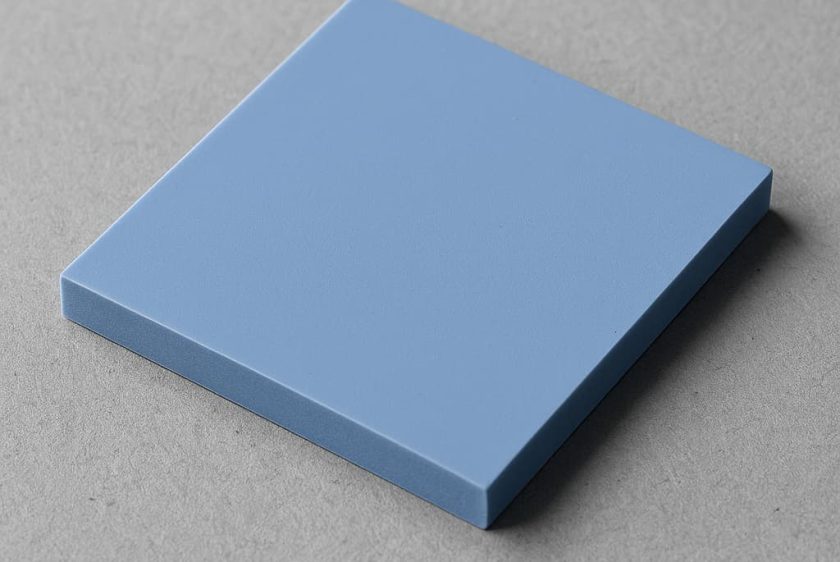

A thermal pad is a soft, compressible material placed between a heat-generating component and a heatsink or cooling solution. Its purpose is to fill air gaps and improve heat transfer between two surfaces.

Unlike air, which is a poor conductor of heat, thermal pads are made from materials with high thermal conductivity, allowing heat to pass more effectively from the component to the cooling device. Thermal pads are often used as an alternative to thermal paste because they are easier to handle, cleaner to apply, and provide consistent coverage.

When two solid surfaces come into contact, microscopic imperfections leave tiny air pockets in between. These gaps trap air, which acts as an insulator. A thermal pad fills those gaps, replacing the insulating air with a conductive medium that transfers heat away from the electronic component.

By improving surface contact, thermal pads ensure that heat flows efficiently from the device, such as a CPU, GPU, or power transistor to the heatsink or cooling assembly, where it can dissipate into the surrounding air.

Thermal pads come in different materials and configurations depending on performance needs and usage. The most common types include:

These are the most widely used and cost-effective. They are flexible, easy to cut to size, and provide adequate thermal conductivity for standard applications such as consumer electronics.

Graphite pads offer higher thermal conductivity compared to silicone pads. They are thin, durable, and suitable for high-performance applications such as gaming laptops, GPUs, and servers.

These pads soften and flow slightly when exposed to heat, improving contact between surfaces. They combine the convenience of pads with the thermal performance of pastes.

Ceramic particles are added to silicone pads to enhance thermal conductivity. They are often used in industrial or automotive electronics requiring better heat dissipation.

Manufacturers sometimes provide pre-cut pads tailored for specific devices, such as gaming consoles or VR headsets, ensuring proper fit and maximum efficiency.

Thermal pads are versatile and used across a wide range of devices and industries. Some common applications include:

In many cases, thermal pads are chosen over thermal paste when the application requires easy installation, reusability, or larger surface coverage.

These benefits make thermal pads a popular choice for both manufacturers and end-users.

While convenient, thermal pads generally offer lower thermal conductivity compared to high-quality thermal pastes. They are also less effective for applications where extreme performance is required, such as competitive overclocking in gaming PCs. For most consumer and professional electronics, however, thermal pads provide a practical balance of ease and efficiency.

Deciding between a thermal pad and thermal paste depends on your use case:

In some systems, both may be used depending on the location and thermal demands of each component.

Thermal pads are a crucial element in modern electronics, providing an effective and user-friendly solution for managing heat. By filling microscopic gaps between surfaces, they ensure efficient heat transfer, protect components, and maintain reliable performance. Whether you are building a PC, upgrading your gaming console, or maintaining industrial equipment, understanding the role of thermal pads can help you make better decisions for cooling solutions.