Foam tapes are versatile adhesive materials used across a wide range of industries and applications. Known for their ability to seal, cushion, insulate and bond, these tapes come in various formulations to meet specific performance needs. Whether you are in automotive manufacturing, construction, or electronics assembly, understanding the different types of foam tapes and their unique properties can help ensure the right product is used for the job.

This article explores the key types of foam tapes available today, their properties, industry applications, and how to select the most suitable tape for your needs.

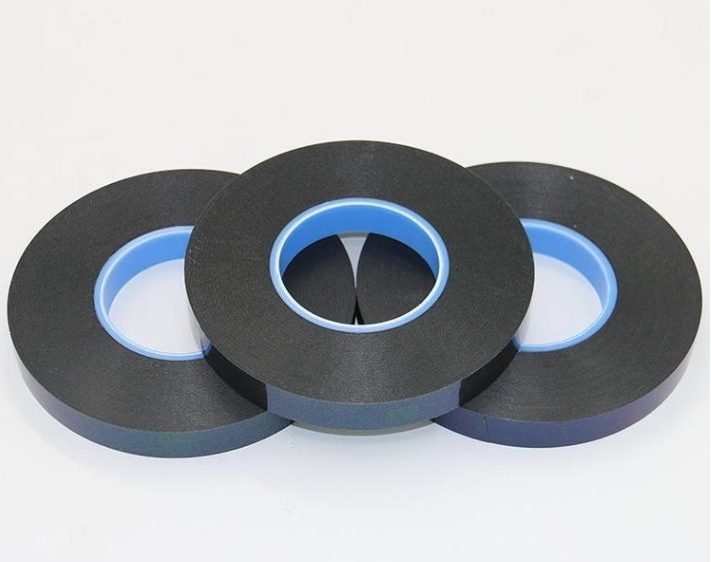

Foam tape is an adhesive tape made with a foam backing, often designed for cushioning, sealing, or bonding applications. The foam can vary in density, thickness, and material composition, with options for single-sided or double-sided adhesives.

Depending on the formulation, foam tape may be resistant to temperature changes, moisture, vibration, and UV exposure. These characteristics make it ideal for both indoor and outdoor use, particularly in environments where flexibility and long-term adhesion are required.

Foam tapes are categorized primarily by the material used in the foam layer. Each type offers unique properties suited for specific environments and use cases.

PE foam tape is widely used for general-purpose applications. It is closed-cell, providing good moisture resistance and cushioning. Due to its lightweight and cost-effectiveness, PE foam tape is often used in mounting, insulation, and sealing tasks where moderate strength is sufficient.

Check out our range of PE foam tapes here!

PU foam tape features an open-cell structure that allows air and moisture to pass through. It is commonly used for acoustic insulation and vibration dampening. Its softness and flexibility make it ideal for sealing irregular surfaces, especially in the electronics and appliance sectors.

PVC foam tape is a durable option with strong resistance to UV light, weathering, and chemicals. It is usually employed in outdoor sealing applications such as window glazing or HVAC insulation. Its semi-rigid nature helps maintain structural integrity over time.

Acrylic foam tape offers superior bonding strength and durability. Often used as an alternative to mechanical fasteners, it provides excellent resistance to high temperatures, solvents, and environmental stress. It is commonly seen in automotive and industrial bonding applications where structural strength is critical.

Check out our acrylic foam tapes here!

Neoprene foam tape is known for its excellent resistance to oil, solvents, and weathering. It combines durability with flexibility, making it suitable for harsh environments. This type is often used in HVAC systems, marine applications, and industrial gasketing.

The functionality of foam tape is defined by several performance characteristics that determine its suitability for various applications.

Foam tapes absorb vibrations, making them ideal for use in automotive and machinery components. They help minimize rattling, reduce wear, and prolong the lifespan of adjoining parts.

The compressibility of foam provides effective cushioning between surfaces. This helps in reducing impact damage and contributes to thermal and acoustic insulation in construction and electronics.

Many foam tapes, particularly those with closed-cell structures, offer strong sealing properties against moisture, dust, and air. This is essential in weatherproofing doors, windows, and HVAC systems.

Foam tapes can withstand a range of temperatures, which is important in automotive and industrial settings. High-performance tapes, like acrylic foam, maintain adhesion and structural integrity even under thermal cycling.

The resilient structure of foam allows it to absorb shocks, protecting sensitive equipment and maintaining the integrity of joints in dynamic environments.

Foam tapes are employed across various industries for both structural and non-structural purposes.

In the automotive sector, foam tapes are commonly used for weatherstripping, noise reduction, and panel bonding. Their ability to handle vibrations and exposure to varying temperatures makes them reliable for interior and exterior applications. We have an article going through the types of automotive tapes used in the industry, make sure to check it out.

Foam tapes play a critical role in construction for window glazing, HVAC sealing, and thermal insulation. Their sealing properties help improve energy efficiency and indoor comfort while protecting against environmental elements.

In electronics, foam tapes are used for gasket sealing, securing lightweight components, and providing insulation. Their ability to conform to tight spaces and resist vibration is especially valuable in compact, sensitive assemblies.

Foam tapes also find a place in everyday tasks such as packaging, appliance mounting, and DIY projects. They offer a convenient, mess-free solution for attaching or sealing materials without the need for screws or nails.

Foam tapes are available in both single-sided and double-sided adhesive formats. Single-sided foam tapes are typically used for sealing, cushioning, and insulation where only one side needs to adhere to a surface. These are common in weatherstripping or soundproofing applications.

Double-sided foam tapes, on the other hand, provide adhesion on both sides, making them suitable for mounting, bonding, or joining two surfaces. They are often used in signage, displays, or panel installations where a clean, invisible bond is required. The choice between the two depends on whether the application involves sealing or bonding functions.

| Feature | Single-Sided Foam Tape | Double-Sided Foam Tape |

|---|---|---|

| Adhesive Sides | One side only | Adhesive on both sides |

| Primary Use | Sealing, cushioning, insulation | Mounting, bonding, joining surfaces |

| Common Applications | Weatherstripping, soundproofing | Signage, displays, panel installations |

| Visibility After Application | Often visible, used more for functional purposes | Typically hidden between surfaces for a clean finish |

| Function | Sealing and protection | Bonding and holding materials together |

Selecting the appropriate foam tape involves evaluating several key factors to ensure optimal performance and durability.

Different foam adhesives bond better with certain materials. For example, acrylic foam tape adheres strongly to metal and glass, while PE foam tape works well with plastics and painted surfaces. It is essential to match the tape’s adhesive properties to the substrate.

The intended use plays a major role in tape selection. Sealing applications may require a soft, conformable foam like PU, whereas structural bonding demands high-strength acrylic foam. Consider whether the tape is for temporary or permanent use.

Environmental conditions, including temperature and humidity, affect tape performance. If the tape will be exposed to heat or UV light, choose a tape that maintains adhesion and structural integrity under those conditions, such as neoprene or acrylic foam.

Foam tapes are indispensable tools in a wide variety of applications due to their unique combination of adhesion, flexibility, and resilience. Understanding the differences between foam types—such as polyethylene, polyurethane, PVC, acrylic, and neoprene—enables better selection for specific tasks.

Whether you are looking to seal out moisture, absorb shock, or create a long-lasting bond, choosing the right foam tape ensures reliability and performance. By considering the application, surface type, and environmental conditions, you can confidently select a foam tape that meets your needs while maximizing longevity and efficiency. Explore our range of adhesive tapes today!