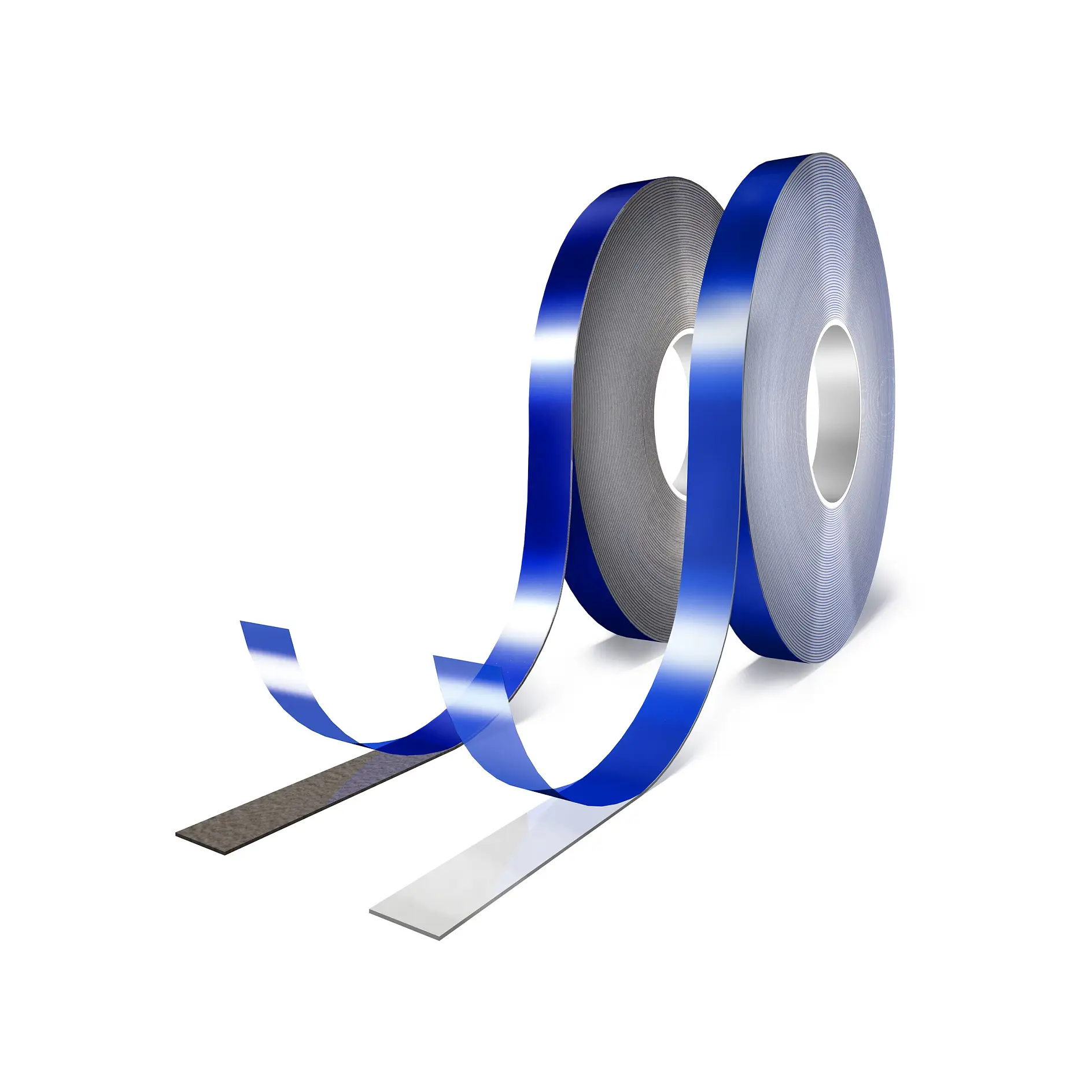

What is Tesa 7042?

Tesa 7042 is a high-performance double-sided acrylic foam tape designed for versatile and durable bonding applications. With a thickness of 500μm, it combines strong adhesion, excellent stress absorption, and superior temperature resistance. Available in gray and white, Tesa 7042 ensures aesthetically pleasing, invisible bonding for decorative elements and structural assemblies. Its advanced acrylic adhesive formula enables strong bonding to challenging surfaces such as powder-coated metals and plastics, making it ideal for high-demand industrial and decorative uses.

Composition and Structure

- Base Material: Acrylic foam core with viscoelastic properties for stress absorption and material tolerance compensation

- Adhesive Type: Pure acrylic adhesive, delivering high adhesion strength and durability

- Total Thickness: 500μm (0.5mm), providing a balance of cushioning, filling, and flexibility

- Color Options: Gray and white, to match various application surfaces for an invisible finish

- Elongation at Break: 770%, enabling the tape to accommodate material movements and deformations without failure

- Temperature Resistance:

- Short-term: Up to 200°C for temporary high-heat exposure

- Long-term: Up to 120°C for sustained use in elevated temperature environments

- Bonding Strength (after 3 days):

- ABS: 22N/cm

- PMMA: 17N/cm

- Stainless Steel: 23N/cm

- Glass: 21N/cm

- Aluminum: 23N/cm

- Other Properties:

- High initial adhesion

- Excellent UV (anti-aging), moisture, and chemical resistance

- Good static shear resistance at both 23°C and 70°C

- Strong T-type clamp performance for mechanical holding

Key Properties

- Medium thickness (500μm): Provides effective cushioning, stress relief, and adaptability to irregular surfaces

- High bonding strength: Maintains strong adhesion to metals, glass, plastics, and powder-coated surfaces

- Excellent stress dispersion: Absorbs and distributes dynamic stresses, reducing risks of bond failure

- High elongation at break (770%): Adapts to thermal expansion, contraction, and mechanical movements

- Superior temperature resistance:

- Up to 200°C short-term

- Up to 120°C long-term

- Outstanding environmental resistance: Withstands UV exposure, moisture, and chemicals without degradation

- Invisible bonding: Gray and white colors match application surfaces, creating seamless visual integration

- Bubble-free bonding: Smooth application without trapped air for high-quality finishes

Applications of Tesa 7042

- Decorative Panel Bonding:

- Secure bonding of refrigerator glass doors, dishwasher panels, and other decorative panels, providing invisible bonding without affecting product appearance

- Decorative Element Bonding:

- Fixing window pane trims, decorative strips, and other embellishments, ensuring reliable and aesthetic installation

- Glass-to-Glass and Glass-to-Metal Bonding:

- Reliable assembly of glass partitions, glass doors, and metal-glass combinations, offering high bond strength with stress dispersion to prevent cracking

- Industrial Applications:

- Used in electronics, machinery, and automotive industries for bonding and fixing components where strong adhesion, temperature resistance, and aesthetic bonding are critical

Features & Benefits of Tesa 7042

- High-performance acrylic adhesive: Strong and durable bonding on metals, plastics, glass, and coated surfaces

- Balanced thickness (500μm): Medium thickness for versatility in decorative and structural applications

- Excellent stress absorption: Prevents material stress concentration and bond failure under dynamic conditions

- High elongation (770%): Accommodates thermal and mechanical movements of bonded materials

- Wide temperature tolerance: Up to 200°C short-term, 120°C long-term, ensuring reliable performance under heat exposure

- Superior environmental resistance: Long-term durability against UV, moisture, and chemicals

- Color matching (gray/white): Enables invisible bonding to complement product aesthetics

- Bubble-free application: Smooth and even adhesion for quality appearance and performance

- High initial adhesion and shear resistance: Strong holding power from initial application and over long-term use

Comparison with Other Adhesive Tapes

- Higher elongation at break (770%): More flexible than standard foam tapes for demanding environments

- Strong adhesion on difficult surfaces: Outperforms regular tapes on powder-coated and plastic materials

- Medium-thickness foam: Offers more adaptability and cushioning than thinner adhesive films

- Superior stress absorption and dispersion: Reduces bond failure risk in applications subject to dynamic stress

- High temperature resistance: Operates in harsher environments than conventional double-sided tapes

- Color options for aesthetic bonding: More suited for visible applications needing color-matching adhesives

- Enhanced UV, moisture, and chemical resistance: More reliable in outdoor and industrial settings than typical tapes

Why Choose VST Malaysia?

VST Malaysia offers high-quality bonding solutions like Tesa 7042, designed to meet the demanding needs of industries requiring strong, aesthetic, and reliable adhesives. With superior product knowledge and a customer-first approach, VST Malaysia ensures clients get the best tape solutions for applications ranging from decorative assembly to structural bonding. Our products are trusted for their durability, flexibility, and performance under challenging conditions. Partner with VST Malaysia for innovative adhesive solutions that enhance product quality and reliability.