What is Nitto ELEP HOLDER ELP WS-02T?

Nitto ELEP HOLDER ELP WS-02T is a high-performance UV-curable adhesive tape designed to support semiconductor wafer dicing processes. Before UV curing, the tape firmly holds the wafer in place, and after UV curing, it easily releases die, making it ideal for semiconductor manufacturing.

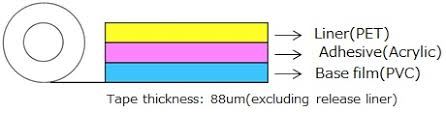

Composition and Structure

- UV-curable adhesive layer that allows firm holding before curing.

- Polymer-based carrier film for stability and easy die pickup.

- RoHSII compliant formulation, ensuring safe and eco-friendly usage.

Key Properties

- Thickness: 0.088 mm, offering precise and reliable dicing support.

- Adhesion Strength: High initial adhesion before UV exposure, low adhesion after UV curing.

- Chipping Performance: Reduces wafer chipping, ensuring a clean dicing process.

- Broad Die Size Compatibility: Suitable for various semiconductor wafer sizes.

Applications of Nitto ELEP HOLDER ELP WS-02T

Semiconductor Industry

- Wafer dicing process

- Die bonding & semiconductor manufacturing

Features & Benefits of Nitto ELEP HOLDER ELP WS-02T

- High Initial Holding Power – Ensures firm wafer attachment during dicing.

- UV Curable Adhesion – Easily releases die after exposure to UV light.

- Excellent Chipping Resistance – Ensures clean cuts and minimal defects.

- Eco-Friendly & RoHSII Compliant – Designed for safe use in manufacturing.

- Flexible & Reliable – Compatible with multiple wafer sizes.

Comparison with Other Adhesive Tapes

- Adhesion Control: Changes from high to low after UV curing, unlike standard tapes.

- Wafer Protection: Minimizes chipping, improving yield rates.

- Peeling Strength: Strong initial hold, easy release post-UV exposure.

Why Choose VST Malaysia?

VST Malaysia supplies genuine Nitto ELEP HOLDER ELP WS-02T with fast delivery, bulk order discounts, and expert technical support. Our high-quality solutions ensure seamless semiconductor wafer processing.