What is Tesa 75410?

Tesa 75410 is a high-performance double-sided acrylic foam tape with a total thickness of 100μm. Engineered for demanding applications, it offers superior vibration and impact resistance combined with excellent adhesion to various substrates. The modified acrylic adhesive ensures high bonding strength, while the acrylic foam core provides flexibility, cushioning, and fit over curved or irregular surfaces. Its black color delivers outstanding light-shielding, effectively preventing light leakage in sensitive electronic and display components. With strong resistance to high temperatures, UV, and aging, Tesa 75410 is a reliable solution for long-term bonding needs.

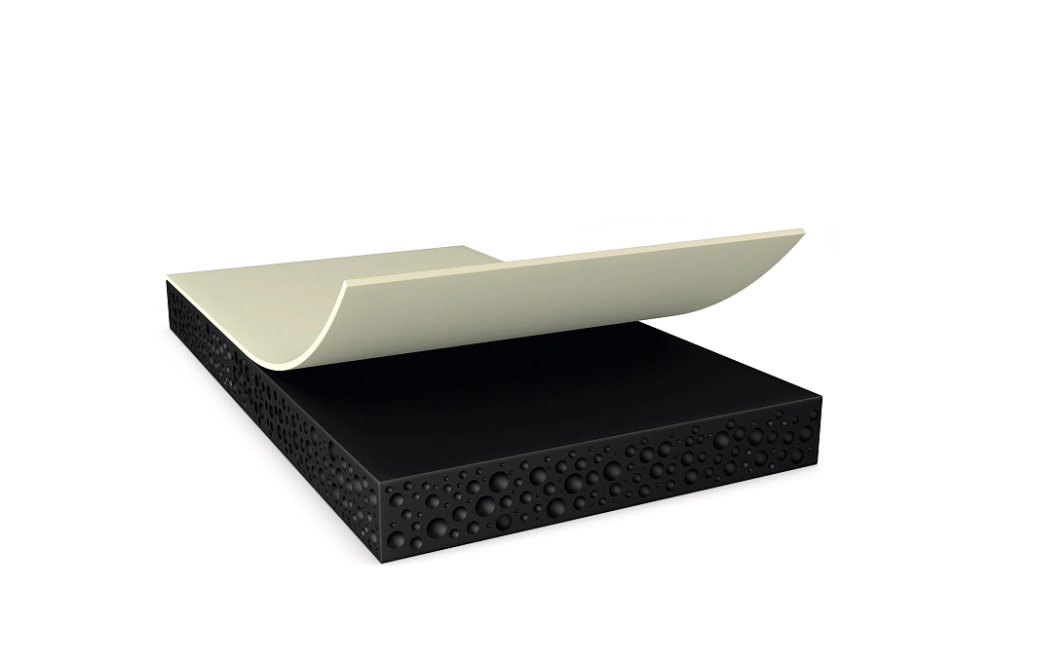

Composition and Structure

- Base Material: Acrylic foam with excellent flexibility, cushioning, and chemical resistance

- Adhesive Type: Modified acrylic for high initial and sustained bonding strength, with superior weather and aging resistance

- Total Thickness: 0.10mm (100μm), suitable for applications with tight space constraints

- Release Paper Type: PET (polyester), 72g/m² weight, 50μm thickness, transparent for precise positioning and application

- Color: Black for effective light-shielding and aesthetic finish

- Light Transmittance: < 0.5% in the 380 – 780nm range, excellent for preventing light leakage in displays

- Temperature Resistance:

- Long-term: 90°C

- Short-term: 140°C

- Bonding Strength:

- Aluminum: 7.2N/cm (initial), 9.4N/cm (after 3 days)

- Glass: 11.4N/cm (initial), 11.9N/cm (after 3 days)

- PC: 9.8N/cm (initial), 12.3N/cm (after 3 days)

- Steel: 11.6N/cm (initial), 13.1N/cm (after 3 days)

Key Properties

- Ultra-thin design (100μm): Perfect for slim and compact product assembly

- High initial and long-term bonding strength: Ensures secure adhesion to metals, plastics, and glass

- Excellent vibration, shock, and impact resistance: Protects components from mechanical stress and impact damage

- Outstanding light-shielding (black color): Prevents light leakage in sensitive electronics and displays

- High temperature resistance (up to 140°C short-term): Suitable for high-temperature environments

- Excellent anti-aging and UV resistance: Suitable for outdoor and UV-exposed applications

- Anti-rebound performance: Prevents tape warping, ensuring long-term stability

- Superior chemical stability and dimensional integrity: Reliable for industrial and electronic applications

Applications of Tesa 75410

- Electronic Equipment Field: Used for bonding internal components such as chips, batteries, and display screens in smartphones, tablets, and other devices. Ensures stable component placement and prevents loosening under vibration or impact. Suitable for assembling electronic shells and covers with excellent sealing properties

- Automobile Manufacturing Field: Ideal for bonding interior components such as dashboards, center consoles, and door panels. Provides cushioning and vibration dampening to reduce noise. Also used for mounting automotive electronics like navigation systems and audio units, ensuring secure fit even in harsh driving conditions

- Home Appliance Manufacturing Field: Suitable for assembling panels, display screens, control buttons, and decorative components in home appliances like TVs, refrigerators, and air conditioners. Enhances product appearance and structural stability while providing strong bonding

- Optoelectronic Display Field: Applied in assembling LCD and OLED displays, including bonding polarizers, backlight modules, and touch screens. Its excellent light-blocking and bonding performance ensure display quality and product durability

- Medical Device Field: Used for bonding small parts, sensors, and labels in medical equipment. Offers high chemical stability and biocompatibility, ensuring safety and reliability in medical environments

- Precision Instrument Field: Ideal for securing optical components and mechanical parts in precision instruments such as optical and measuring devices. Maintains accuracy and prevents displacement or loosening that could affect performance

- Advertising and Logo Field: Suitable for mounting advertising materials and logos that require waterproof and light-shielding properties, such as outdoor billboards and lightbox ads. Enhances display contrast and longevity. Also used for assembling light-shielding frames on display equipment to improve screen clarity

Features & Benefits of Tesa 75410

- Ultra-thin profile (100μm): Perfect for applications with minimal available space

- Strong adhesion on various materials: Bonds effectively to metals, plastics, and glass surfaces

- High shock, vibration, and impact resistance: Prevents failure under mechanical stress

- Excellent light-shielding (black color): Prevents light leakage in electronic and optical devices

- Temperature resistance up to 140°C (short-term): Suitable for high-heat environments

- Outstanding UV and aging resistance: Maintains performance over long-term outdoor exposure

- Anti-rebound performance: Ensures long-term flat adhesion without edge lifting

- High chemical and dimensional stability: Consistent performance in industrial and sensitive applications

- Good cushioning and fit: Accommodates irregular or curved surfaces easily

Comparison with Other Adhesive Tapes

- Thinner than most foam tapes (100μm): Suitable for ultra-slim assemblies

- Higher impact and shock resistance: Superior to traditional thin double-sided tapes in mechanical protection

- Enhanced light-shielding capability: Black color blocks light better than clear or white tapes

- Greater thermal and UV resistance: Longer lifespan under heat and sunlight compared to regular adhesive tapes

- Stronger anti-rebound and anti-warping performance: Ensures stability over time, unlike many thin bonding tapes

- Excellent bonding to metals, plastics, and glass: More versatile in multi-material applications

- Flexible foam core: Provides cushioning unlike rigid double-sided tapes

Why Choose VST Malaysia?

VST Malaysia offers high-performance adhesive solutions such as Tesa 75410 to meet the demanding requirements of various industries. Tesa 75410 delivers unmatched bonding strength, ultra-thin profile, and durability, making it an ideal solution for electronics, automotive, home appliances, and precision instruments. Backed by VST Malaysia’s commitment to quality and customer service, Tesa 75410 helps improve product assembly efficiency, reliability, and longevity. Whether you need advanced bonding for electronics, vibration protection in vehicles, or secure assembly for sensitive instruments, Tesa 75410 offers a trusted solution for critical applications.